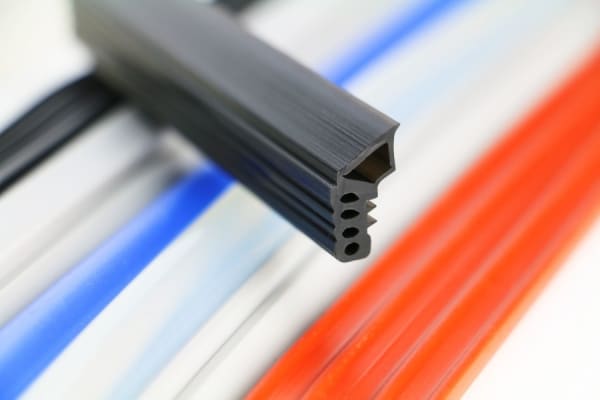

black rubber Our offer includes the processing of orders for the manufacture of various types of rubber products. The rubber compounds we produce are moulded and extruded using raw materials from well-known and renowned world producers. Thanks to the use of a broad base of high-class rubbers with very good physical and chemical properties, we can offer a range of articles intended for many different industries.

black rubber Our offer includes the processing of orders for the manufacture of various types of rubber products. The rubber compounds we produce are moulded and extruded using raw materials from well-known and renowned world producers. Thanks to the use of a broad base of high-class rubbers with very good physical and chemical properties, we can offer a range of articles intended for many different industries.

Properties and applications

Rubbers that are resistant to abrasion and the effects of acids and alkalis will be ideal for the creation of medical devices, as well as shock absorbers or plugs. Acrylonitrile-butadiene rubber, on the other hand, is ideal for creating rubber sealing components for the aerospace, chemical and automotive industries. Chloroprene rubber, which is flame-retardant and resistant to UV radiation and ozone, will provide a base for rubber adhesives used in the construction industry.

Latex rubber

Waterproof and durable latex rubber is used in many industries. The undoubted advantage of the material is that it can be used to form thin sheets from which balloons, gloves or fitness rubbers are produced. Latex rubbers are distinguished by their excellent elasticity, which results in high deformation under the influence of a small external force and the removal of the deformation when the force ceases. As a result, rubber made from natural latex can be stretched to up to 800% of its original length. The material has a high coefficient of friction, is resistant to acid and alkaline corrosion, and provides good thermal insulation, sealing and vibration damping properties.

The exact list of materials used can be found below.

| No. | Chemical name | ASTM designation | Thermal resistance [C] | Advantages | Application |

|---|---|---|---|---|---|

| 1. | cis-polyisoprene natural synthetic | NR IR | - 50 do + 80 | Very good physical-mechanical properties Good abrasion resistance Good resistance to acids and alkalis | General-purpose rubbers Medical devices, corks, plates Dynamic working parts, e.g. shock absorbers |

| 2. | styrene-butadiene | SBR | - 40 do + 100 | Very good physical-mechanical properties Good abrasion resistance Good resistance to acids and alkalis | General-purpose rubber Used as a substitute for NR or in a mixture with it. |

| 3. | acrylonitrile-butadiene | NBR | - 30 do + 120 | Good physical-mechanical properties Good abrasion resistance Good resistance to petroleum oils and greases | Automotive, aerospace, chemical industry. Seals for mechanical equipment, actuators, etc. |

| 4. | chloroprene | CR | - 30 do + 100 | Good physical-mechanical properties Good abrasion resistance Good resistance to weathering UV and ozone Flame retardant | Construction, automotive and other industries Used as a base for rubber adhesives |

| 5. | ethylene-propylene-diene | EPDM | - 40 do + 130 | Very good resistance to weather conditions UV and ozone Good resistance to water and water vapour Good resistance to acids and alkalis | Building industry - window and door seals Automotive, chemical industry |

| 6. | Fluoropolymer | FKM | - 20 do + 250 | Good resistance to petroleum-derived organic liquids, oils, solvents Low gas permeability. Flame-retardant. | Aerospace, chemical, automotive and many other industries |